A friend of mine runs two throttle-by-wire LS throttle bodies on top of a blank top in his Cougar – you can configure whatever you want, really.” “It all just depends on what you want to do – we have plenum tops that’ll take two 4150s or two 4500s, as a carburetor or as a throttle body. “There are also a lot of guys who plumb from the firewall side who’re running the big ‘ice chest’ intercoolers that are mounted in the car,” Dralle notes. There comes a point with a race manifold where you’ve kind of got to say, ‘let’s focus on the performance, and worry a little less about the packaging.’ There’s also just that fun factor of seeing something as racy looking as a Hi-Ram on top of an engine, too.”Īnother cool aspect of the Hi-Ram design is the modularity it provides – builders have several choices in plenum tops, and Holley now also offers side-entry lids that allow for plumbing similar to a typical five-liter. Those considerations helped us to flesh out the rest of the design. The engines that this manifold is going to be used on are likely to make peak torque at 5000 to 6000 RPM, and they’re going to make peak power above 7000 RPM.

The Hi-Ram is the opposite – we using a shorter runner, and we’re trying to make it as direct as possible.

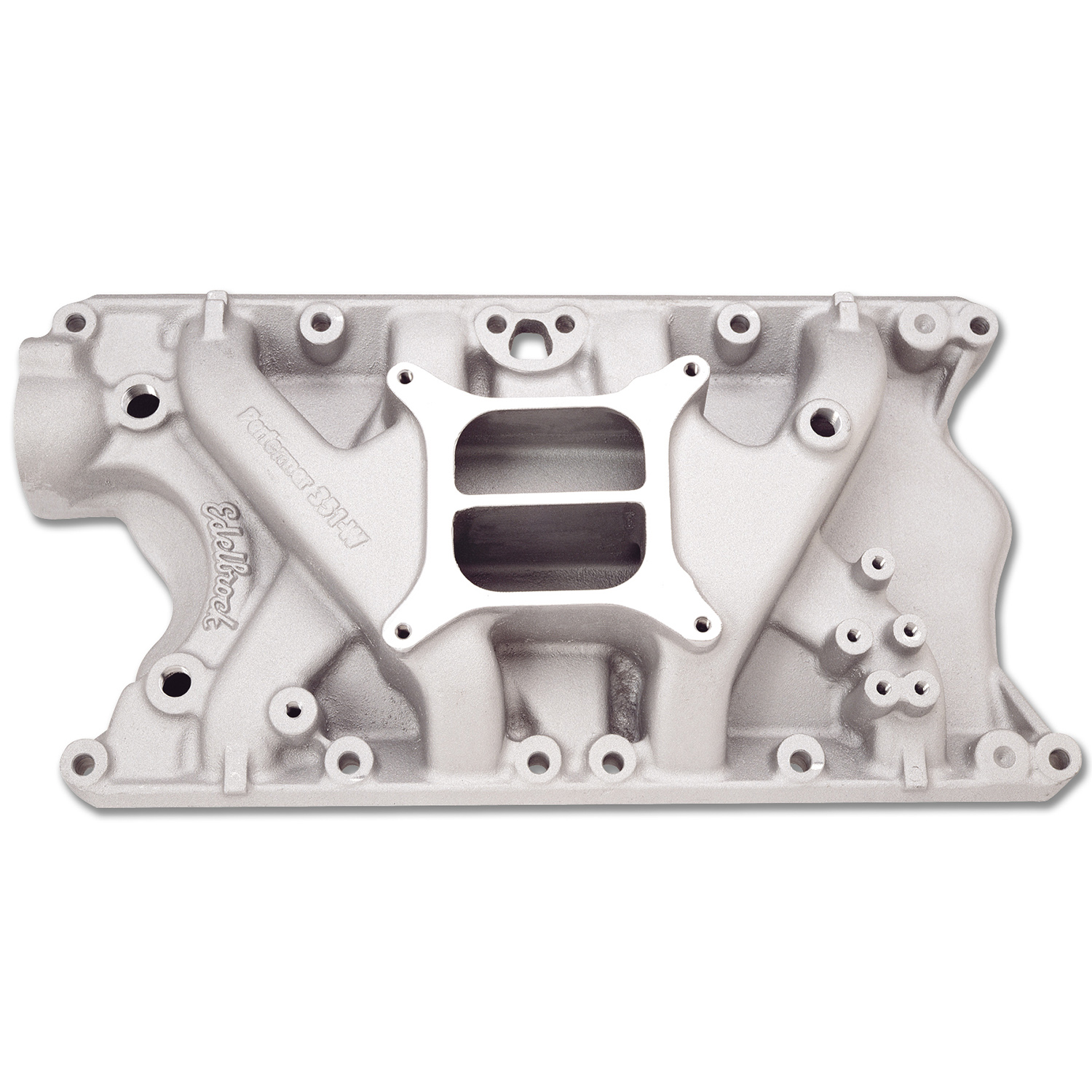

#351w intake manifold how to

“The factory is trying to make peak torque at, say, 3000 RPM, and then you’re trying to figure out how to package eighteen inches of runner and make it fit under the hood. With the Hi-Ram, Holley is also not limited by some of packaging constraints that an OE-style manifold must adhere to. The plenum designs also have to be such that we’re not creating problems with things like recirculation – with an EFI lid, that’s much more an issue that it would be with something like a traditional two-carb setup.” “You’re going to a central plenum, runners that are fairly straight, and as few flow restrictions into the runner itself as possible. “In many ways, it’s very much like your traditional tunnel-ram type drag racing manifold that would have had a pair of carburetors on top of it,” Dralle says. The Hi-Ram intake, by contrast, employs a very different design approach. These straight, beefy runners provide an unobstructed path into the heads, just as the horsepower gods intended. And with that we can not only create models of things like this intake manifold, but also associated parts – like the distributor it needs to work with – so we can ensure the packaging works the way we want it to.”

“That provides us with very tight control on the part design.

#351w intake manifold software

“Everything we do is fully solid modeled in software like Creo or Solidworks,” he tells us. “Having to deal with a distributor, a water outlet – addressing packaging concerns became a priority early on.”įortunately, modern engineering technologies make this aspect of the development process much less of a trial-and-error proposition than was in decades past. “The biggest challenge with the 351W EFI Hi-Ram development was dealing with all the stuff that isn’t on an LS engine,” Dralle explains. Similarities between the LS cylinder head and the popular high performance Ford Windsor heads on the market allowed Holley to hit the ground running when prototyping this new intake manifold, but there were also a number of Windsor-specific considerations that needed to be sussed out along the way. There is some street stuff, but I think when you look at classes like NMRA Hot Street from back in the day, there’s a lot of 400+ cubic-inch Windsors out there that live at the strip.” And those racers tend to choose combinations like these out of preference rather than necessity, so Holley sought to compliment these potent, high-winding mills with a manifold that could keep up. “We’d finished the work on the LS3, cathedral port, and LS7, and we felt that the 351W builders could use some more options here, so it seemed like a natural progression.”ĭralle notes that the folks building potent 351W-based engines tend to gravitate toward a more specific niche of the market than the LS stuff does, though, and those circumstances helped guide the overall approach to this manifold’s design. “This manifold actually grew out of the program for LS Hi-Ram series,” says Jim Dralle, senior design engineer for Holley Performance. With that in mind, a few years ago Holley set to work on an effort to bring fuel injected 351W-based engines into its Hi-Ram intake manifold lineup. The Hi-Ram’s design puts a modern twist on the old school tunnel ram design.

0 kommentar(er)

0 kommentar(er)